6Kw 8Kw 12Kw 15Kw Raycus Multi-Module Cw Fiber Laser Source

165036 INR/Piece

Product Details:

- Length Standard Module Length, varies by module

- Cutting Speed 0-100 mm/s depending on material

- Tool Type Multi-Module Fiber Laser

- Cutting Capacity Up to 40 mm carbon steel, 50 mm stainless steel

- Hardness Industrial Grade

- Machine Type Fiber Laser Cutting Machine Compatible

- Material Laser Source with Integrated Fiber Module

- Click to view more

X

6Kw 8Kw 12Kw 15Kw Raycus Multi-Module Cw Fiber Laser Source Price And Quantity

- 1 Piece

- 165036 INR/Piece

6Kw 8Kw 12Kw 15Kw Raycus Multi-Module Cw Fiber Laser Source Product Specifications

- Multi-Module Fiber Laser

- Continuous Wave (CW) Laser Cutting

- Up to 40 mm carbon steel, 50 mm stainless steel

- Standard Module Length, varies by module

- 0-100 mm/s depending on material

- Laser Source with Integrated Fiber Module

- Industrial Grade

- Fiber Laser Cutting Machine Compatible

- Rectangular Module

- Laser Cutter

- 0.03 mm

- Automatic/Remote Control

- No External Coating

- High Power Laser Force

- Multi-Mode Continuous

- High efficiency, customizable power, real-time status monitoring

6Kw 8Kw 12Kw 15Kw Raycus Multi-Module Cw Fiber Laser Source Trade Information

- 7 Days

Product Description

| Body Material | Cylindrical |

| Application | Industrial |

| Country of Origin | Made in India |

| Portable | Yes |

| Model Name/Number | MAX Fiber Laser Source 2-6KW |

| Display | Auto |

| Color | Golden |

| Brand | Quick CNC Technologies |

Advanced Multi-Module Technology

Raycus fiber laser sources utilize multi-module continuous wave (CW) technology to achieve customizable high power outputs suited for challenging industrial applications. This design guarantees consistent performance and extended service life beyond 100,000 hours, making it ideal for demanding manufacturing environments.

Precision and Power for Sheet Metal Cutting

With cutting capacities up to 40 mm for carbon steel and 50 mm for stainless steel, this fiber laser source ensures accuracy (0.03 mm) and speed (up to 100 mm/s). Its integrated protection features and compatibility with mainstream laser heads establish it as a reliable solution for sheet metal cutting.

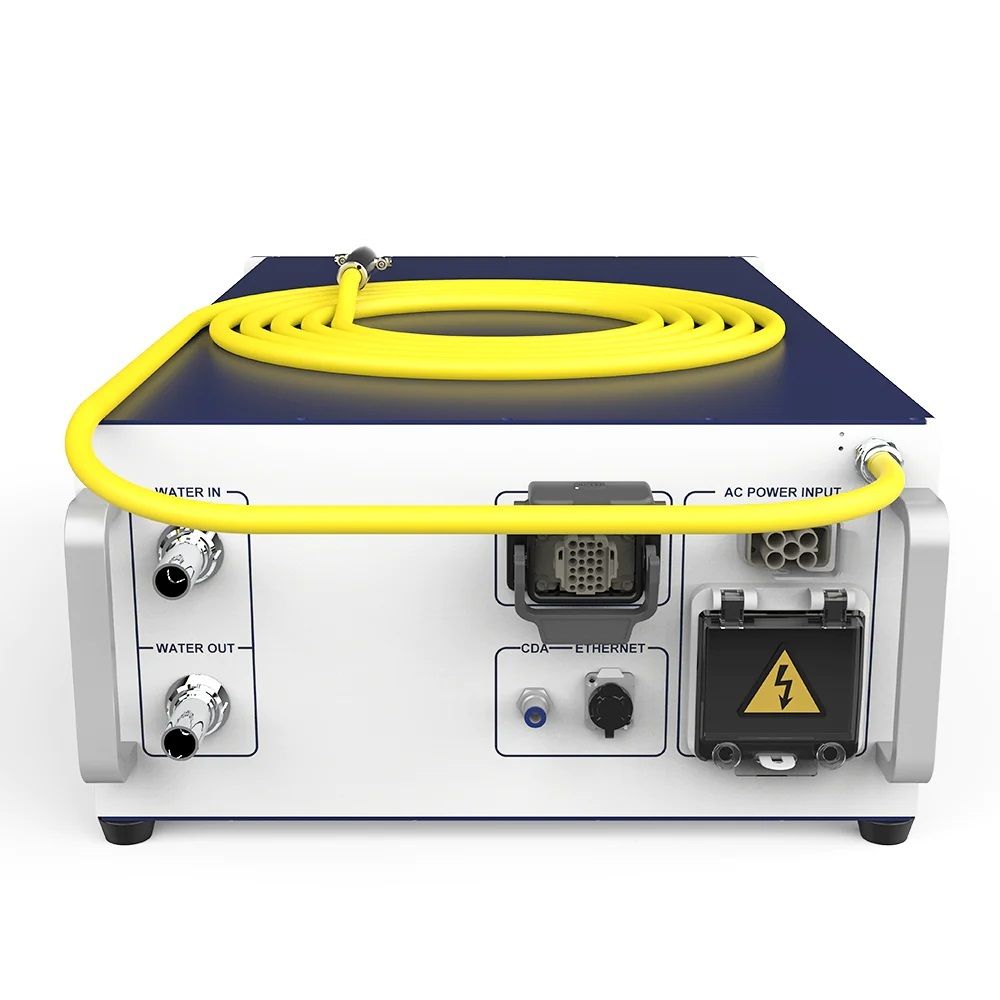

Efficient Cooling and Robust Integration

The water cooling system maintains optimal operating temperatures, supporting performance in ambient conditions from 10C to 40C and relative humidity less than 70%. The product integrates easily with various fiber laser cutting machines and supports automatic or remote control.

FAQs of 6Kw 8Kw 12Kw 15Kw Raycus Multi-Module Cw Fiber Laser Source:

Q: How does the Raycus Multi-Module CW Fiber Laser Source benefit industrial sheet metal cutting operations?

A: This laser source offers high cutting speeds, exceptional precision, and the ability to process thick carbon and stainless steels. Its continuous wave operation ensures smooth edges and consistent quality, improving workflow efficiency and accuracy in industrial fabrication.Q: What is the typical process for integrating this fiber laser source into manufacturing automation systems?

A: Integration is facilitated by standard communication interfaces like RS232/RS485 and Ethernet. The source is compatible with mainstream cutting heads and automatic or remote control systems, making installation direct and adaptable for various automation setups.Q: Where can this fiber laser source be used most effectively?

A: It is ideally suited for industrial environments such as sheet metal workshops, fabrication facilities, and manufacturing automation plants in India and globally, especially where high power and robust cutting accuracy are required.Q: What measures ensure the safe and reliable operation of this fiber laser?

A: Safety and reliability are maintained through built-in protection features, including over-temperature, over-current, and water flow monitoring, alongside power stability 2%. The water cooling system and high-quality industrial-grade construction enhance operational durability.Q: When is it recommended to choose different power output levels for the Raycus fiber laser source?

A: Choose higher power outputs like 12kW or 15kW for thick material processing and large-scale fabrication. Lower outputs such as 6kW and 8kW are suitable for thinner sheets or less intensive applications, optimizing energy use and operating costs.Q: How long can users expect the Raycus fiber laser source to operate reliably?

A: Thanks to its multi-module design and industrial-grade construction, the service life exceeds 100,000 hours under proper maintenance, ensuring long-term reliability and minimal downtime for production lines.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese