Fiber Laser Source

450000 INR/Number

Product Details:

- Measurement Corneal curvature, height, power map

- Objective Non-contact corneal surface analysis

- Lens High-resolution plano-convex lens

- Theory Placido disk-based reflection method

- Product Type Fiber Laser Source

- Material MS

- Size Standard

- Click to view more

X

Fiber Laser Source Price And Quantity

- 1 Piece

- 450000 INR/Number

Fiber Laser Source Product Specifications

- Fiber Laser Source

- Standard

- Non-contact corneal surface analysis

- Corneal curvature, height, power map

- High-resolution plano-convex lens

- MS

- Placido disk-based reflection method

Fiber Laser Source Trade Information

- EXW

- 15 Days

- All India

Product Description

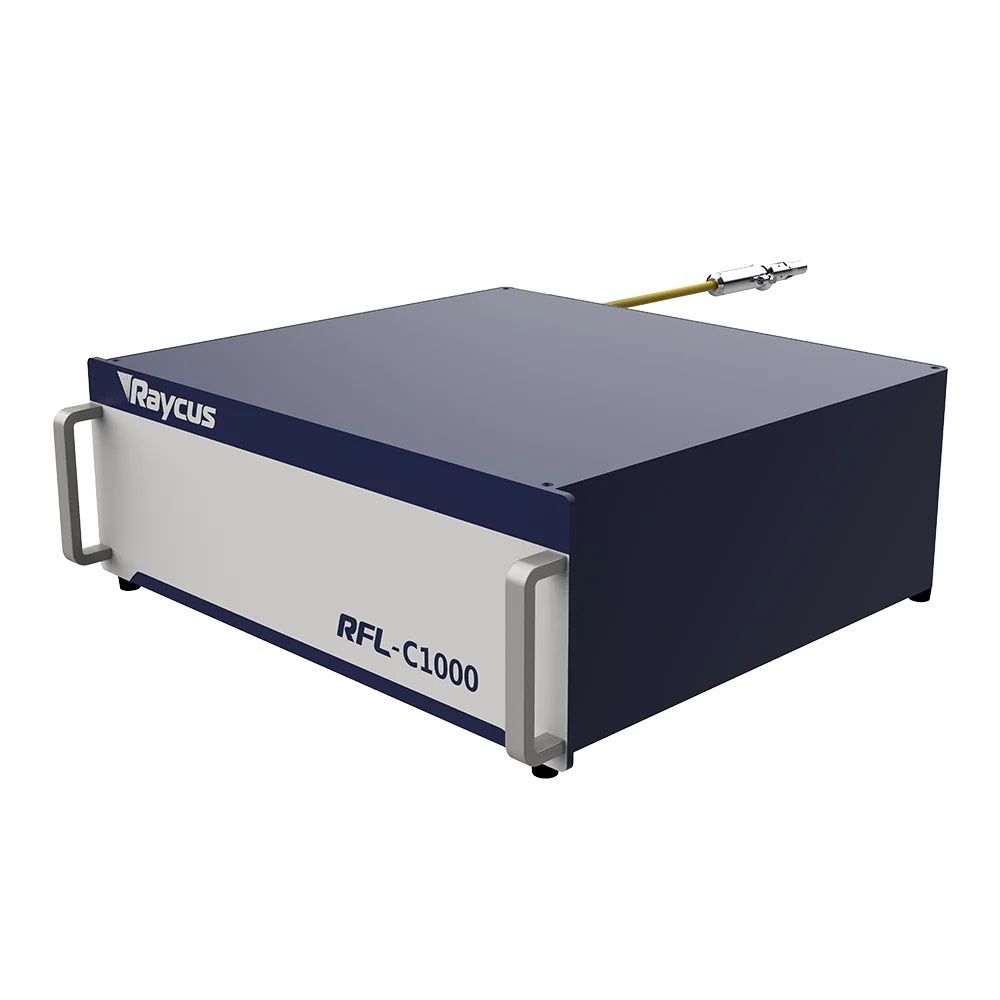

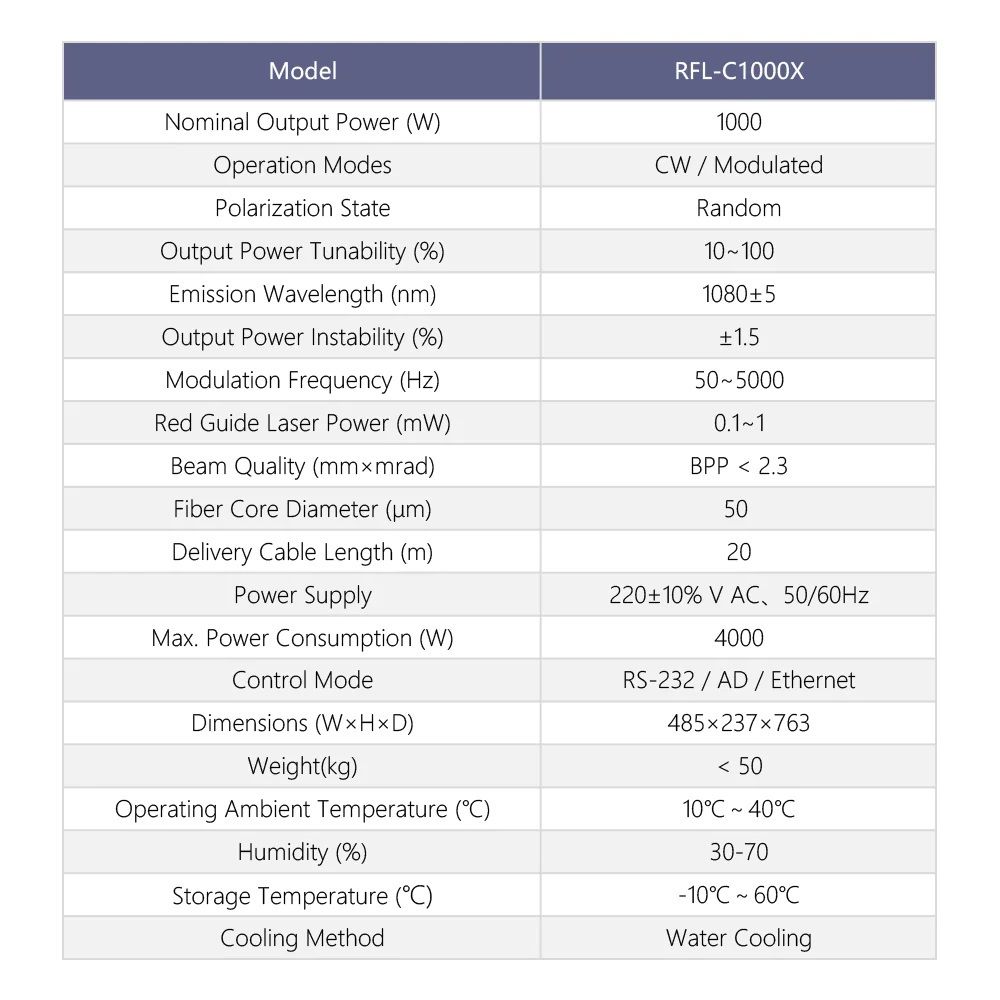

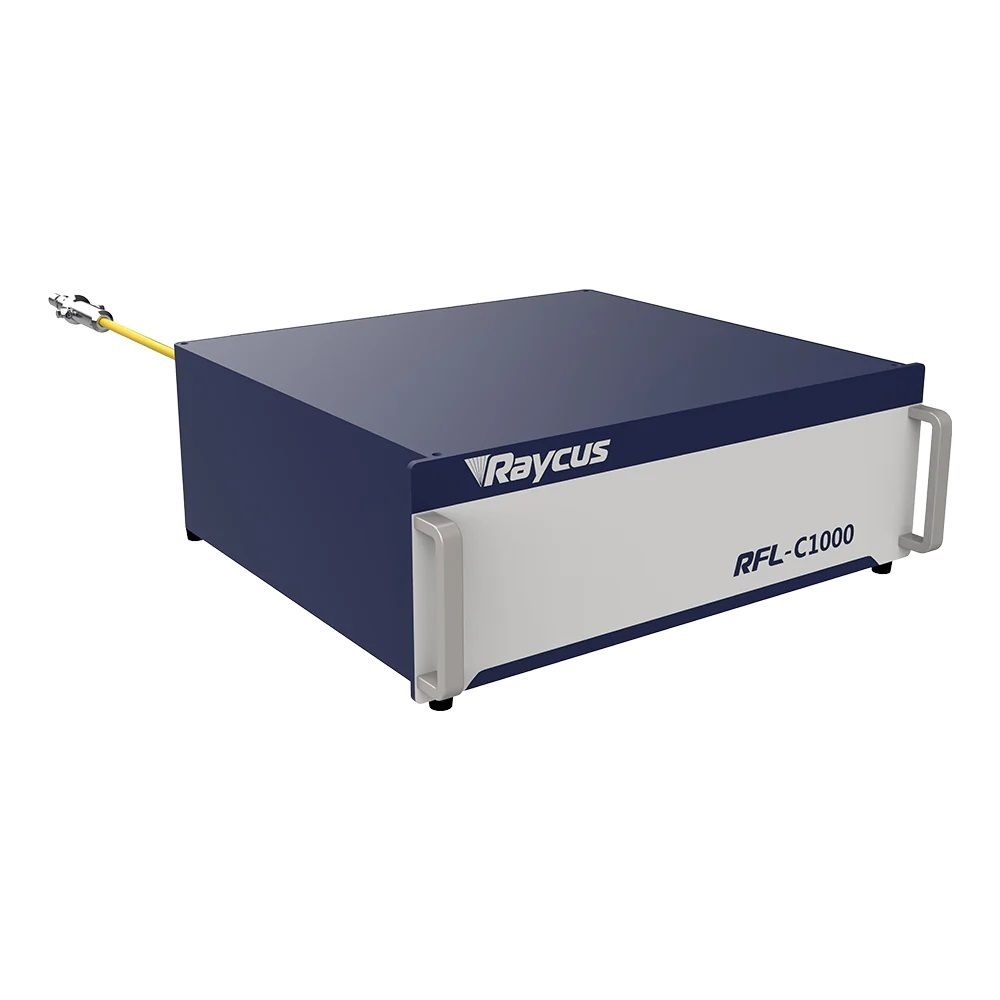

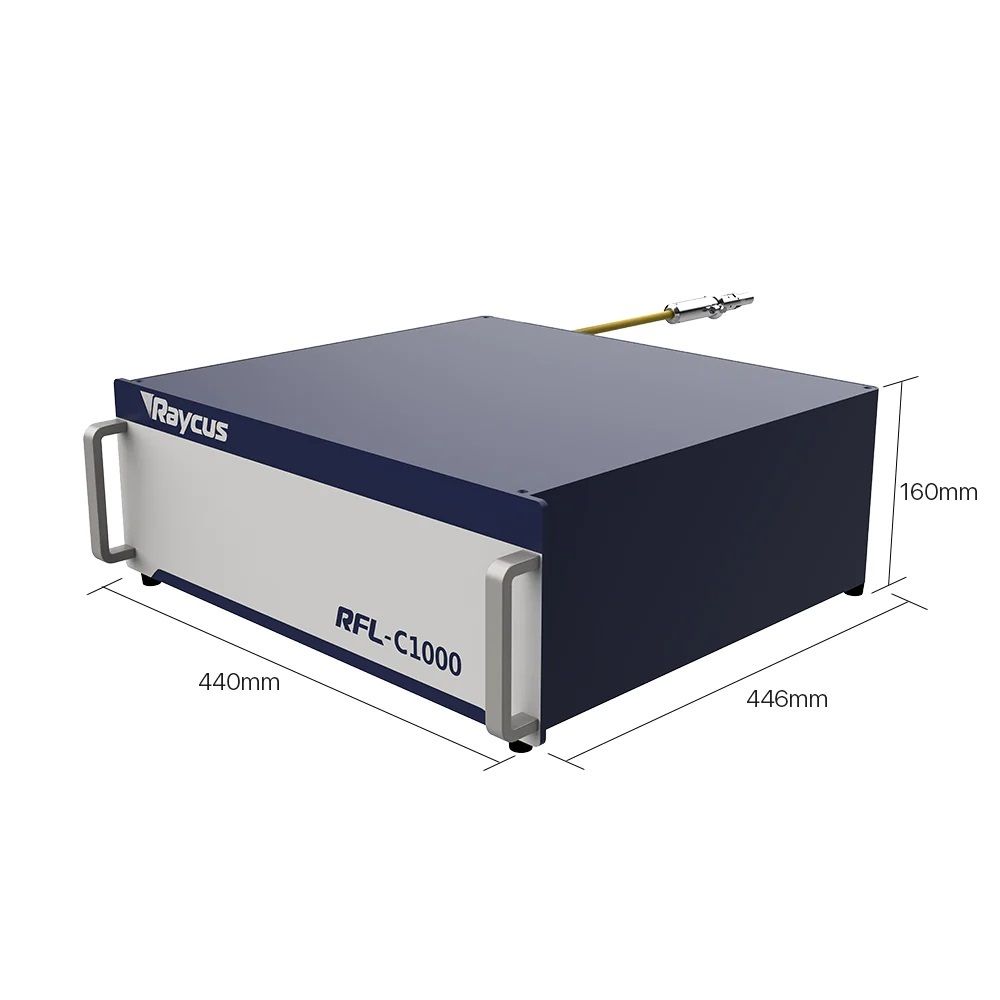

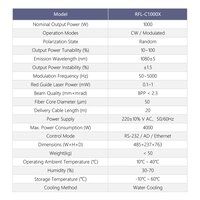

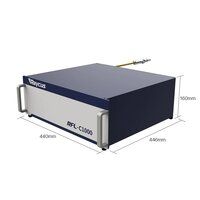

Discover the Fiber Laser Source 3KW from Quick CNC Technologies, a noble solution remarked for its praiseworthy precision in non-contact corneal surface analysis. Harnessing the rare Placido disk-based reflection method, this device offers unbeatable price and performance for industrial use. Fabricated from durable MS with a cylindrical body and multi-color finish, its high-resolution plano-convex lens ensures high accuracy for measuring corneal curvature, height, and power map. Portable, water-cooled, and made in India, this opportunity is ending soon for discerning service providers, suppliers, and traders.

Advantages & Applications of Fiber Laser Source

The Fiber Laser Source stands out for its advanced non-contact analysis and high-resolution measurement. Its praiseworthy design enables reliable corneal curvature, height, and power map readings, making it noble equipment for industrial and medical applications. The durable MS cylindrical build ensures longevity and multi-color appearance. Primary competitive advantages include superior accuracy, portable construction, and rare Placido disk-based technology, positioning it as an industry-leading solution for precise surface assessments.

Supply Ability, Sample Policy & Packaging Details

We maintain an outstanding supply ability for the Fiber Laser Source, ensuring prompt shipment of goods across India. Sample policy is available for select providers, subject to terms. Packaging details assure secure transport, with delivered units safely encased for protection during shipment. Our streamlined process promises timely delivery and reliable condition upon receipt. For service providers, traders, and suppliers, every shipped item meets strict quality standards, guaranteeing satisfaction upon arrival.

Advantages & Applications of Fiber Laser Source

The Fiber Laser Source stands out for its advanced non-contact analysis and high-resolution measurement. Its praiseworthy design enables reliable corneal curvature, height, and power map readings, making it noble equipment for industrial and medical applications. The durable MS cylindrical build ensures longevity and multi-color appearance. Primary competitive advantages include superior accuracy, portable construction, and rare Placido disk-based technology, positioning it as an industry-leading solution for precise surface assessments.

Supply Ability, Sample Policy & Packaging Details

We maintain an outstanding supply ability for the Fiber Laser Source, ensuring prompt shipment of goods across India. Sample policy is available for select providers, subject to terms. Packaging details assure secure transport, with delivered units safely encased for protection during shipment. Our streamlined process promises timely delivery and reliable condition upon receipt. For service providers, traders, and suppliers, every shipped item meets strict quality standards, guaranteeing satisfaction upon arrival.

| Body Material | Cylindrical |

| Application | Industrial |

| Country of Origin | Made in India |

| Portable | Yes |

| Model Name/Number | Fiber Laser Source 3KW |

| Color | Multi color |

| Brand | Quick CNC Technologies |

FAQ's of Fiber Laser Source:

Q: How does the Placido disk-based reflection method enhance measurement accuracy?

A: The Placido disk-based reflection method provides precise, non-contact mapping of the corneal surface, resulting in superior accuracy for curvature, height, and power map measurements compared to conventional techniques.Q: What applications are suitable for the Fiber Laser Source 3KW?

A: This device is engineered for industrial use, particularly in non-contact corneal surface analysis, quality control in manufacturing, and precision surface measurement tasks.Q: When can I expect delivery after ordering the Fiber Laser Source?

A: Order shipment is typically processed promptly, with delivery timelines depending on the shipping location within India. Packaging ensures goods are delivered securely and in excellent condition.Q: Where is the Fiber Laser Source manufactured and supplied from?

A: The Fiber Laser Source 3KW is made in India by Quick CNC Technologies and supplied nationally to service providers, suppliers, and traders.Q: What is the process for requesting a sample unit of the Fiber Laser Source?

A: Sample requests can be made based on our sample policy. Eligible parties should contact us directly to discuss sample terms, shipment, and conditions.Q: How beneficial is the fiber laser cooling mode?

A: The integrated water cooling mode maintains optimal performance during intensive operation, ensuring longevity, consistent measurement quality, and reliability for users.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese