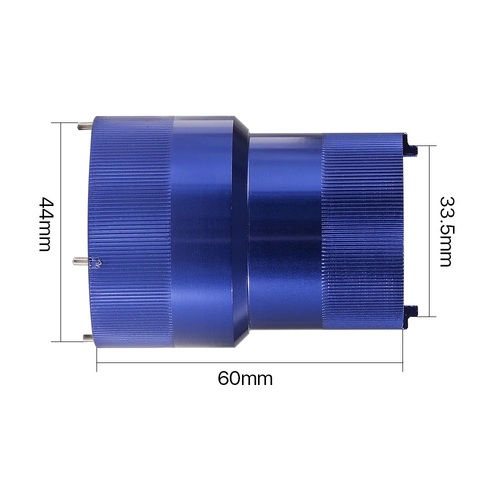

Nozzle For Laser Machine

650 INR/Piece

Product Details:

- Shape Cylindrical

- Cutting Force Suitable for laser cutting applications

- Machine Type Laser Cutting Machine

- Hardness High Hardness (Typically 45-60 HRC depending on material)

- Cutting Accuracy High Precision

- Cutting Capacity Dependent on laser power and type

- Length Standard lengths (e.g., 15-30mm)

- Click to view more

X

Nozzle For Laser Machine Price And Quantity

- 10 Number

- 550.00 - 600.00 INR/Piece

- 650 INR/Piece

- Copper/Brass tone

- Standard (e.g., M11, M14, M16 depending on machine)

- High resistance to thermal damage

- CO2, Fiber, and other laser machines

- Polished

- Low, easy to clean and replace

- Laser cutting, laser engraving, industrial use

- For focusing and directing the laser beam for precision cutting

- Individual/Box Pack

Nozzle For Laser Machine Product Specifications

- No Coating

- Precision machined, corrosion resistant, excellent heat dissipation

- Standard sizes available (e.g., 1.0mm, 1.5mm, 2.0mm)

- Automatic

- Copper or Brass

- Optimized for high-speed laser cutting

- Fitted to laser head, non-manual operation

- Nozzle

- Laser Machining

- Standard lengths (e.g., 15-30mm)

- Dependent on laser power and type

- Laser Machine Nozzle

- High Hardness (Typically 45-60 HRC depending on material)

- High Precision

- Cylindrical

- Suitable for laser cutting applications

- Laser Cutting Machine

- Copper/Brass tone

- Standard (e.g., M11, M14, M16 depending on machine)

- High resistance to thermal damage

- CO2, Fiber, and other laser machines

- Polished

- Low, easy to clean and replace

- Laser cutting, laser engraving, industrial use

- For focusing and directing the laser beam for precision cutting

- Individual/Box Pack

Product Description

| Country of Origin | Made in India |

| Type | Thread Type |

| Material | Brass |

| Pipe Size | 2 inch |

| Color | Copper |

| Machine Type | Laser Cutting Machine |

| CNC or Not | Yes |

| Laser Type | Fiber Laser |

| Usage/Application | Pipe Nozzle |

| I Deal In | New Only |

| Nozzle Diameter | 1.5 inches |

Precision-Crafted for Industrial Laser Machines

This laser machine nozzle is meticulously engineered from robust copper or brass, ensuring durability, corrosion resistance, and maximum heat dissipation during intense laser operations. Its precision machining and polished surface contribute to its extraordinary accuracy and consistent performance, meeting the demands of modern manufacturing environments.

Compatibility and Versatile Applications

The nozzle fits seamlessly with CO2, Fiber, and other laser machines commonly found in cutting and engraving setups. Standard thread sizes (M11, M14, M16) allow easy adaptation to various machine heads, making it suitable for service providers, suppliers, and traders across India. Its versatile role enables high-precision work for a broad range of industrial uses.

Efficient Operation and Maintenance

Requiring minimal maintenance, this nozzle is designed for easy cleaning and trouble-free replacement. Packaged individually or in box packs, it supports automated, non-manual operation, delivering focused laser beams for exacting cuts and engravings. Its shape and construction optimize cutting force and speed, ensuring smooth, reliable processes.

FAQ's of Nozzle For Laser Machine:

Q: How does the nozzle improve laser cutting and engraving precision?

A: The nozzle is designed to focus and precisely direct the laser beam, resulting in cleaner, more accurate edges during cutting or engraving. Its high-hardness copper or brass construction and polished finish minimize thermal distortion and enhance the quality of the laser process.Q: What laser machine types are compatible with this nozzle?

A: This nozzle is compatible with CO2, Fiber, and other mainstream laser machine types used in industrial cutting and engraving. It supports standard thread specifications such as M11, M14, and M16, fitting a wide range of machine heads.Q: Where can this nozzle be used in India?

A: The nozzle is suitable for use in service centers, by suppliers, traders, and manufacturers across India. It is ideal for industrial settings, fabrication units, and workshops employing laser cutting and engraving technologies.Q: What is the maintenance process for this nozzle?

A: Routine maintenance involves simple cleaning to remove debris or residue. The nozzle's design allows quick removal and replacement, which helps sustain optimal performance and reduces downtime in busy operations.Q: What benefits does the copper/brass material provide for laser machining?

A: Copper and brass offer excellent heat dissipation, corrosion resistance, and high hardness, which collectively protect the nozzle from thermal damage during prolonged laser use. These properties ensure longevity and reliable operation in demanding industrial processes.Q: When should the nozzle be replaced or cleaned?

A: It is advisable to inspect the nozzle regularly and clean it whenever you notice debris buildup or a decline in cutting accuracy. Replacement is suggested if signs of wear, blockage, or damage are present, keeping the laser process consistent and precise.Q: What process is used to install and operate this nozzle?

A: The nozzle is attached to the laser machine head using its standard threaded design, allowing for secure and straightforward installation. Operation is fully automatic, with the nozzle directing the laser beam during machining without manual intervention.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese