Precitec H Type Laser Cutting Nozzles

650 INR/Piece

Product Details:

- Material MS

- Usage Industrial

- Click to view more

X

Precitec H Type Laser Cutting Nozzles Price And Quantity

- 1 Piece

- 650 INR/Piece

- Precitec H-head

- Polished

- Copper tone

- Precision machined

- Conical

- Box packing

- High wear resistance

- O2, N2, Air

- Screw-in design

- Single/Double Layer

- Fiber/CO2 laser

- Laser cutting

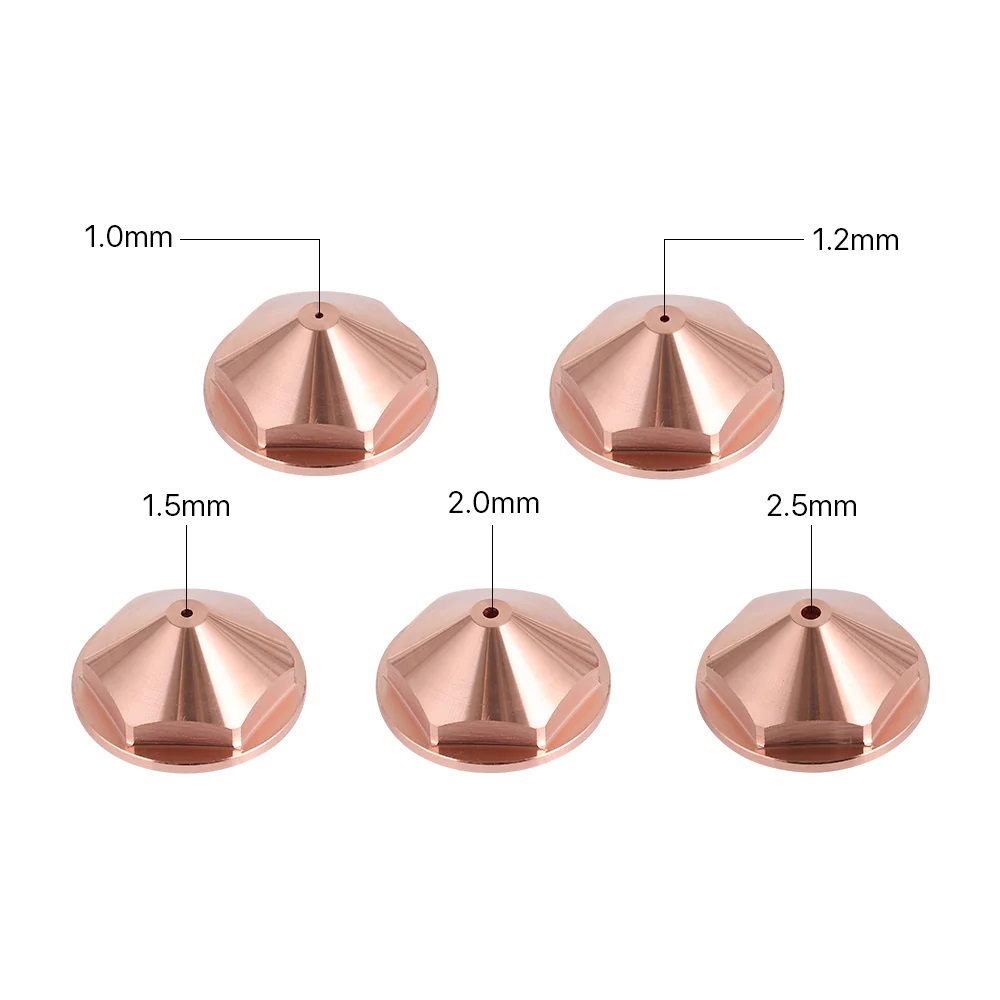

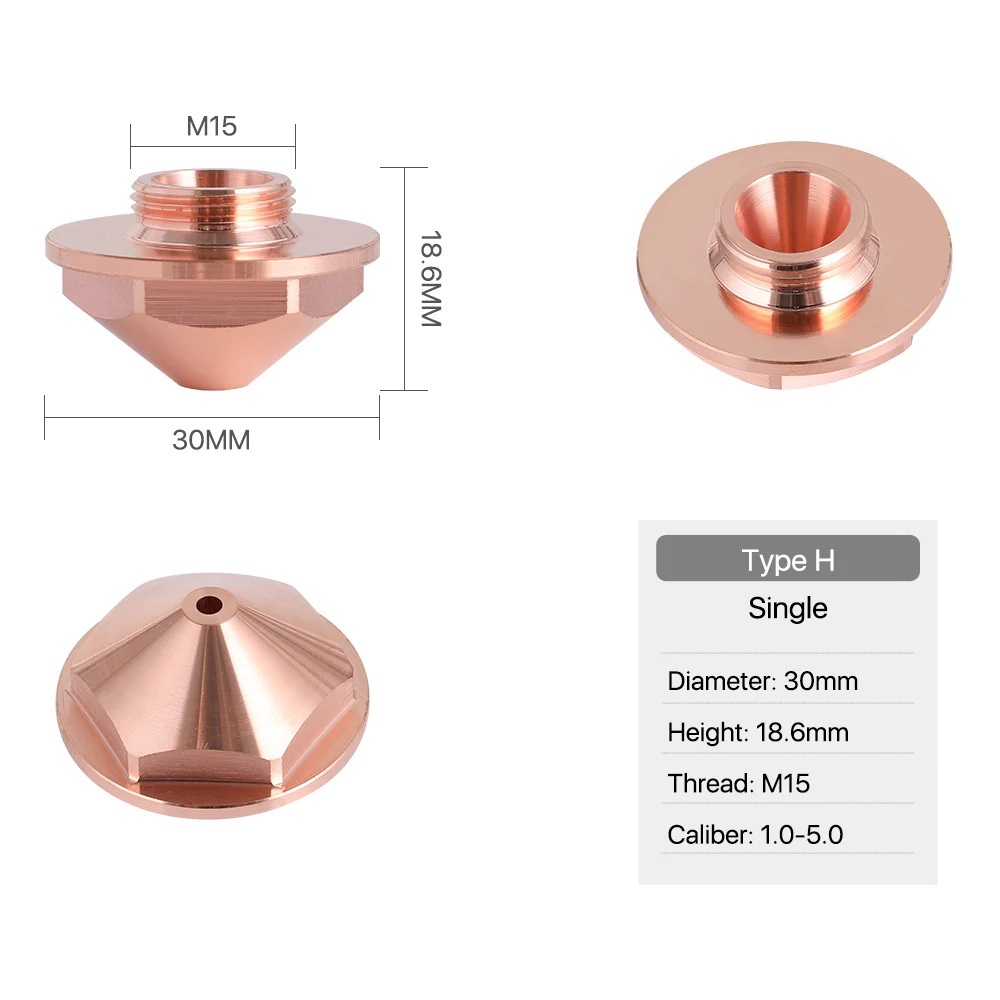

Precitec H Type Laser Cutting Nozzles Product Specifications

- Industrial

- MS

- Precitec H-head

- Polished

- Copper tone

- Precision machined

- Conical

- Box packing

- High wear resistance

- O2, N2, Air

- Screw-in design

- Single/Double Layer

- Fiber/CO2 laser

- Laser cutting

Precitec H Type Laser Cutting Nozzles Trade Information

- 7 Days

Product Description

Experience the sizzling performance of our Precitec H Type Laser Cutting Nozzles-highlighted for their inestimable precision and stellar durability. These popular nozzles, crafted from first-rate MS material and finished in a polished, copper tone, are perfect for laser cutting professionals seeking high wear resistance. Compatible with both Fiber and CO2 lasers, they feature a precision-machined, screw-in mounting, available in both single and double layer conical shapes. Seamless operation with O2, N2, and Air propels their industrial popularity across service providers and traders in India. Superior packaging ensures your nozzles arrive in stellar, ready-to-use condition.

Widespread Use and Competitive Edge of Precitec H Type Nozzles

Precitec H Type Laser Cutting Nozzles are widely used by industry-leading service providers, suppliers, and traders for diverse laser cutting tasks. Application places include automotive workshops, fabrication units, and heavy engineering facilities. The nozzles' primary competitive advantages lie in their inestimable precision, stellar wear resistance, and compatibility with multiple gases and laser types. Their first-rate conical design further enhances cutting efficiency, making them a trusted tool in demanding industrial environments.

Payment and Exportation of Precitec H Type Nozzles

For purchasing Precitec H Type Laser Cutting Nozzles, the asking price and proposal amount are shared upon inquiry, ensuring transparency in transactions. Our Goods Transport services ensure swift and reliable product delivery. Sample policies are available to help evaluate first-rate quality before bulk orders. Main export markets include Asia, the Middle East, and Africa, offering stellar support for businesses worldwide seeking enduring precision in laser cutting solutions.

Widespread Use and Competitive Edge of Precitec H Type Nozzles

Precitec H Type Laser Cutting Nozzles are widely used by industry-leading service providers, suppliers, and traders for diverse laser cutting tasks. Application places include automotive workshops, fabrication units, and heavy engineering facilities. The nozzles' primary competitive advantages lie in their inestimable precision, stellar wear resistance, and compatibility with multiple gases and laser types. Their first-rate conical design further enhances cutting efficiency, making them a trusted tool in demanding industrial environments.

Payment and Exportation of Precitec H Type Nozzles

For purchasing Precitec H Type Laser Cutting Nozzles, the asking price and proposal amount are shared upon inquiry, ensuring transparency in transactions. Our Goods Transport services ensure swift and reliable product delivery. Sample policies are available to help evaluate first-rate quality before bulk orders. Main export markets include Asia, the Middle East, and Africa, offering stellar support for businesses worldwide seeking enduring precision in laser cutting solutions.

FAQ's of Precitec H Type Laser Cutting Nozzles:

Q: How do I mount the Precitec H Type Laser Cutting Nozzles on my machine?

A: These nozzles feature a precision-machined, screw-in design, making installation fast and secure on compatible Precitec H-head systems.Q: What are the main advantages of using a single or double layer nozzle?

A: Single layer nozzles are ideal for low-pressure applications, while double layer options provide enhanced cooling and better performance at high gas pressures during challenging cutting tasks.Q: When should I replace Precitec H Type Laser Cutting Nozzles?

A: It is advisable to replace the nozzles when there is visible wear, decreased cutting performance, or any signs of nozzle blockage, ensuring consistent, first-rate results.Q: Where can these nozzles be applied?

A: They are suitable for use in industrial fabrication shops, manufacturing plants, automotive facilities, and any laser-cutting environment that uses Fiber or CO2 lasers with compatible gas systems.Q: What is the process for ordering and receiving these nozzles?

A: To order, contact the supplier for the asking price and proposal amount. Upon confirmation, the nozzles are packaged securely and delivered via reliable Goods Transport services.Q: How does using Precitec H Type Nozzles benefit my business?

A: They provide inestimable precision, high wear resistance, and compatibility with various gases, ensuring efficient and cost-effective laser cutting operations.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese