Friendess Extend Board Fiber Laser Cutting Control System

39000 INR/Piece

Product Details:

- Material High Speed Steel

- Hardness Yes

- Operation Type Finishing

- Usage Industrial Automation

- Coating Yes

- Size Standard Sizes

- Product Type CNC Laser Cutter

- Click to view more

X

Friendess Extend Board Fiber Laser Cutting Control System Price And Quantity

- 39000 INR/Piece

- 1 Piece

- 24V DC

- Ethernet Supported

- Industrial Automation

- Fiber Laser Cutting

- Digital IO

- CNC Laser Cutter

- Panel Mount

- Extend Board

- Friendess Controller Only

- Precision Control

Friendess Extend Board Fiber Laser Cutting Control System Product Specifications

- CNC Laser Cutter

- Standard Sizes

- Yes

- High Speed Steel

- Yes

- Finishing

- Industrial Automation

- 24V DC

- Ethernet Supported

- Industrial Automation

- Fiber Laser Cutting

- Digital IO

- CNC Laser Cutter

- Panel Mount

- Extend Board

- Friendess Controller Only

- Precision Control

Friendess Extend Board Fiber Laser Cutting Control System Trade Information

- 5-10 Days

- All India

Product Description

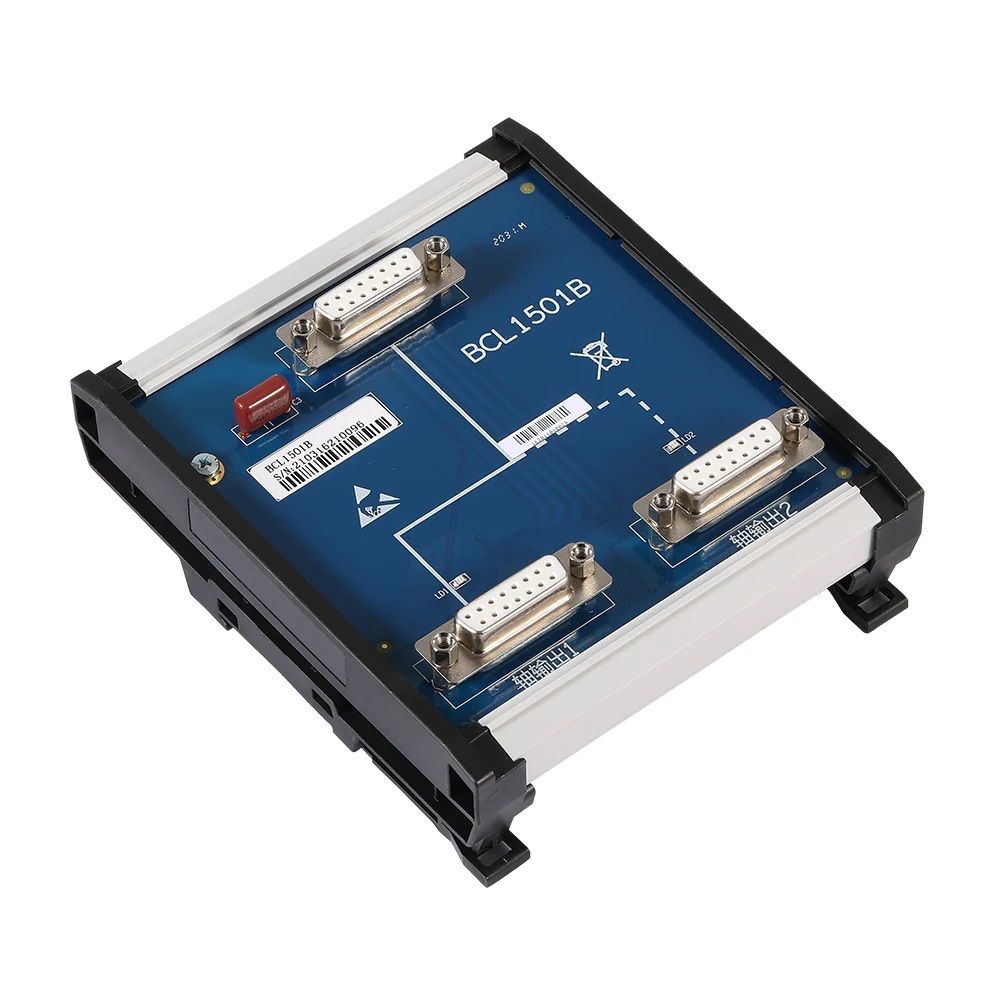

FRIENDESS EXTEND BOARD FIBER LASER CUTTING CONTROL SYSTEM

We have brought a FRIENDESS EXTEND BOARD FIBER LASER CUTTING CONTROL SYSTEM, which is a progressive software-based system. It is been made to control the operation of a fiber laser cutting machine. The board refers to the additional circuit board that can be added to the control system. It is done to increasing its functionality and capabilities. FRIENDESS EXTEND BOARD FIBER LASER CUTTING CONTROL SYSTEM has a user friendly operation, which allows the operator to program and control the laser beam in a simple manner. It provides clean cuts with minimum heat generation.

Seamless Integration and Flexible Connectivity

Equipped with digital IO and Ethernet communication, the Friendess Extend Board ensures easy integration into existing CNC laser cutting setups. Its panel mount design facilitates straightforward installation, making it suitable for industrial environments focused on automation and finishing tasks. Standard sizing presents enhanced compatibility and reduced downtime during upgrading or maintenance.

Precision Control for Industrial Automation

Engineered for state-of-the-art fiber laser cutting, the system delivers unmatched precision. Supported by a robust 24V DC input and constructed from coated, high-speed steel, it is ideal for rigorous finishing operations. The control type guarantees stable and precise management across various industrial automation processes.

Dedicated Usage for Enhanced Efficiency

Designed exclusively for Friendess controllers, this extend board bolsters workflow and operational efficiency in CNC laser cutters. It streamlines complex automation, providing industrial suppliers and service providers with dependable, easy-to-operate solutions for their cutting-edge requirements.

FAQ's of Friendess Extend Board Fiber Laser Cutting Control System:

Q: How does the Friendess Extend Board improve precision control in fiber laser cutting applications?

A: By integrating with Friendess controllers and utilizing digital IO and Ethernet, the Extend Board offers meticulous management of cutting processes, allowing for accurate adjustments and consistent finishing quality in CNC laser cutting tasks.Q: What is the recommended process for installation and panel mounting of the Extend Board?

A: The board is designed for straightforward panel mounting. Users should ensure compatibility with standard sizes and connect the digital IO and Ethernet interfaces as per the provided technical guidelines, using a 24V DC input to power the system.Q: When is it best to use the Friendess Extend Board in industrial automation?

A: It is most effective when precision and reliability are required, such as during finishing operations in CNC laser cutters, especially when utilizing high speed steel materials in demanding industrial environments.Q: Where can the Friendess Extend Board Fiber Laser Cutting Control System be sourced in India?

A: The system is available through authorized service providers, suppliers, and traders specializing in industrial automation products across India.Q: What are the benefits of using a system compatible only with Friendess controllers?

A: This exclusive compatibility ensures optimized performance, seamless integration, reduced errors, and increased workflow reliability in automation setups tailored to Friendess hardware.Q: How does the use of hardened, coated, high speed steel enhance the board's performance?

A: These material properties contribute to durability and longevity, ensuring the extend board withstands high-stress environments and maintains consistent operation and precision over time.Q: What types of industrial automation tasks can benefit from the Extend Board's features?

A: Tasks requiring high precision, reliable control, and efficient finishing-such as laser cutting and automated processing-are significantly enhanced by the system's advanced control capabilities, robust construction, and flexible interface options.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese