ORIGINAL RAYTOOLS LASER CUTTING CERAMICS

2550 INR/Piece

Product Details:

X

ORIGINAL RAYTOOLS LASER CUTTING CERAMICS Price And Quantity

- 2550 INR/Piece

- 1 Piece

- Raytools Machines

- Smooth Glazed

- Fiber Laser

- Up to 500°C

- Industrial Cutting

- Screw Thread

ORIGINAL RAYTOOLS LASER CUTTING CERAMICS Trade Information

- 7 Days

Product Description

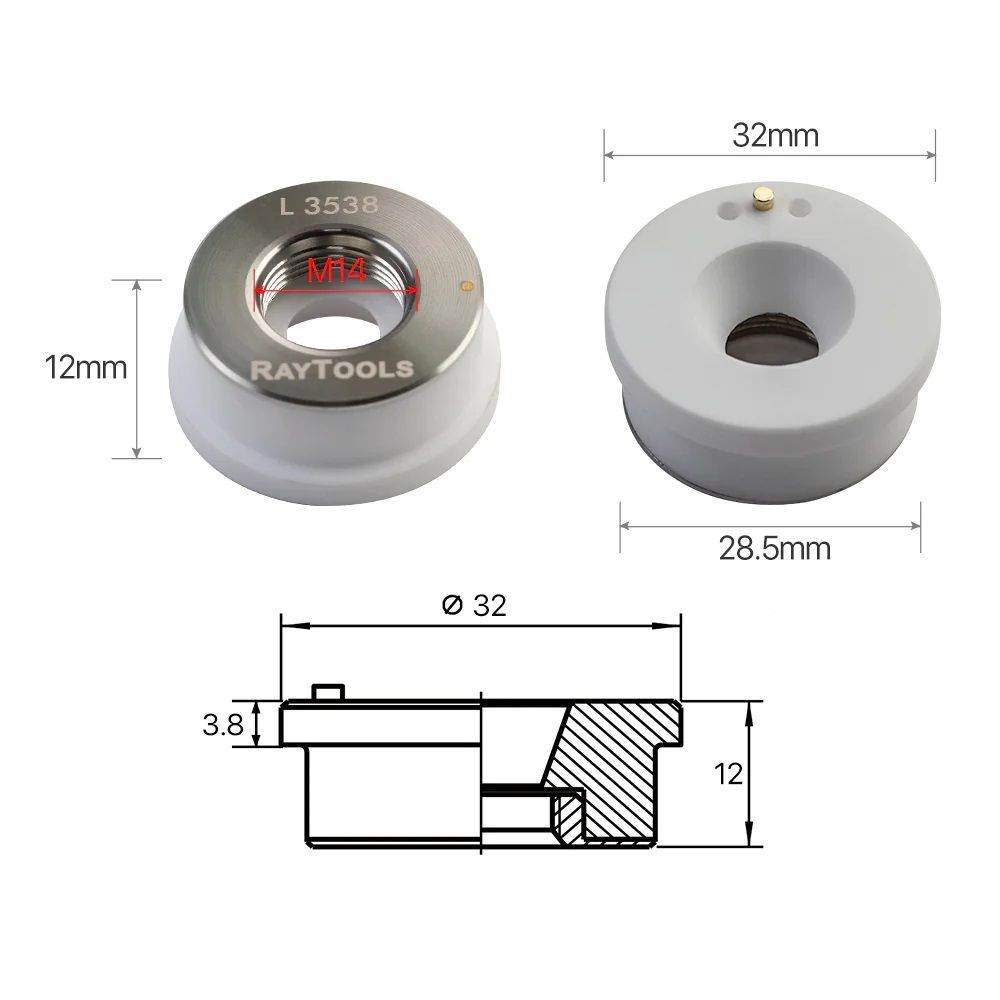

Our company is enthusiastically engaged in offering ORIGINAL RAYTOOLS LASER CUTTING CERAMICS which help in precisely cutting and shaping ceramic materials. It is of paramount importance especially for those that seek to produce fragile, hard, or have complex shapes that are difficult to achieve with traditional cutting methods. The applications of such ceramics are many, including the production of precision components for the electronics and aerospace sectors. ORIGINAL RAYTOOLS LASER CUTTING CERAMICS are also demanded for generating the medical use and design components. Thus, laser cutting ceramics offer precise and efficient cutting of industrial use materials.

Engineered for Precision and Durability

These Raytools laser cutting ceramics are crafted from high-quality metal and engineered to handle demanding industrial environments. The smooth glazed finish ensures minimal resistance and consistent results during the cutting process, while the robust design supports operation at temperatures reaching 500C. Suitable for fiber laser applications, these ceramics offer the perfect blend of precision and longevity.

Seamless Integration with Raytools Machines

Designed exclusively for Raytools cutting equipment, these ceramics offer straightforward installation with a screw thread mount. Their compatibility guarantees that users experience optimal performance without concerns about fit or functionality. Their simple control features make them user-friendly even for operators with minimal setup experience.

Reliable Supply and Trusted Support

Available through a wide network of service providers, suppliers, and traders across India, these cutting ceramics come with warranty coverage. Customers benefit not only from excellent product quality but also from reliable after-sales support and expert guidance, ensuring smooth operation and rapid problem resolution.

FAQ's of ORIGINAL RAYTOOLS LASER CUTTING CERAMICS:

Q: How are the Raytools laser cutting ceramics installed on machines?

A: These ceramics are designed with a screw thread mount, making installation quick and straightforward on compatible Raytools machines. Simply screw the ceramic component into place for a secure fit and reliable operation.Q: What is the primary benefit of using these ceramics in fiber laser applications?

A: The main advantage is their ability to withstand temperatures up to 500C while maintaining a smooth, glazed surface for precise and efficient cutting. They provide durability, stable performance, and minimal wear during industrial cutting processes.Q: When should these ceramics be replaced during operation?

A: Ceramics should be replaced when you notice signs of wear, damage, or a decline in cutting accuracy. Regular inspection during scheduled maintenance will help ensure continuous high-quality operation.Q: Where can I purchase original Raytools laser cutting ceramics in India?

A: You can obtain these ceramics from authorized service providers, suppliers, and traders throughout India. Be sure to choose verified sellers to guarantee product authenticity and warranty coverage.Q: What process do these ceramics support in laser cutting environments?

A: These ceramics are specifically designed for use in fiber laser cutting processes, acting as insulating and heat-resistant components between the laser head and material being cut. This helps maintain precision and safety during operation.Q: How does the simple control feature of these ceramics benefit users?

A: The simple control design allows for straightforward handling and installation, reducing setup time and minimizing the potential for operator error. This contributes to efficient and hassle-free operation, especially in fast-paced industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese