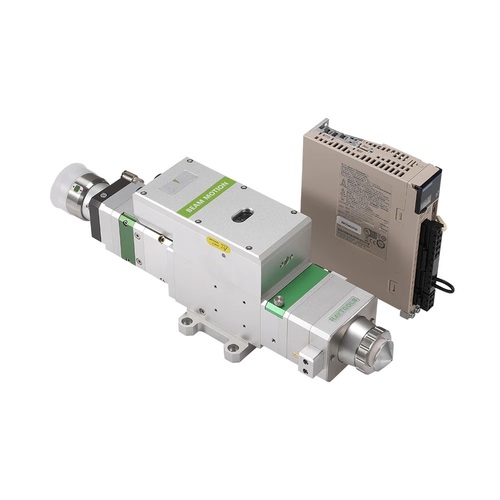

Nozzle Connector For Wsx Mn15 Fiber Laser Cutting Head

25000 INR/Piece

Product Details:

- Material Copper/Brass Alloy

- Features Corrosion Resistant, Heat Resistant, High Durability

- Machine Type WSX MN15 Fiber Laser Cutting Head

- Shape Cylindrical

- Coating Type Uncoated

- Operation Type Fiber Laser Cutting

- Cutting Accuracy High Precision

- Click to view more

X

Nozzle Connector For Wsx Mn15 Fiber Laser Cutting Head Price And Quantity

- 1 Piece

- 25000 INR/Piece

Nozzle Connector For Wsx Mn15 Fiber Laser Cutting Head Product Specifications

- Uncoated

- Cylindrical

- WSX MN15 Fiber Laser Cutting Head

- Corrosion Resistant, Heat Resistant, High Durability

- Copper/Brass Alloy

- Fiber Laser Cutting

- Standard for MN15 Head

- High Hardness

- Standard Length for Wsx MN15

- Automatic

- CNC Machined

- High Precision

- Nozzle Connector

Product Description

A part that joins the laser cutting head to the fibre optic cable that sends the laser beam to the cutting head is the NOZZLE CONNECTOR FOR WSX MN15 FIBER LASER CUTTING HEAD. The nozzle connector typically consists of a metal housing that is designed to hold the nozzle in place and protect it from damage during the cutting process. There are various types of nozzle connectors available in the market where NOZZLE CONNECTOR FOR WSX MN15 FIBER LASER CUTTING HEAD is among the popular one. It maintains the alignment of the cutting head and the fiber optic cable, which is crucial for achieving accurate cuts.

Optimized Performance for Laser Cutting

Engineered to match the specifications of the WSX MN15 Fiber Laser Cutting Head, this nozzle connector ensures reliable and efficient connectivity within your laser cutting machine. The precision machined surface contributes to high-precision cutting results, while the robust copper/brass alloy construction offers resilience under high temperatures and extended operational use.

Effortless Installation and Maintenance

Designed with a user-friendly screw threaded connection and a plug-and-play approach, the connector simplifies installation and replacement. The standard thread type for MN15 nozzle mounts minimizes downtime and ensures that your operations continue smoothly, without the need for specialized installation tools or expertise.

FAQ's of Nozzle Connector For Wsx Mn15 Fiber Laser Cutting Head:

Q: How do I install the Nozzle Connector on the WSX MN15 Fiber Laser Cutting Head?

A: The nozzle connector is designed for easy installation. Simply screw the connector onto the compatible MN15 nozzle mount using the standard thread. The plug-and-play design ensures a secure fit without requiring special tools or technical skills.Q: What materials make up the Nozzle Connector and why are they beneficial?

A: The connector is made from high-hardness copper/brass alloy. This choice of materials offers excellent heat and corrosion resistance, ensuring the connector withstands harsh environments and prolonged laser cutting operations.Q: When should I replace my Nozzle Connector?

A: It is advisable to replace the nozzle connector if you notice wear, reduced cutting accuracy, or visible damage to the connector surface. Regular inspection as part of your maintenance routine helps maintain performance.Q: Where can the Nozzle Connector be used?

A: This connector is specifically compatible with the WSX MN15 Fiber Laser Cutting Head, making it suitable for use in fiber laser cutting machines running the MN15 head, commonly employed in industrial applications.Q: What is the process for maintaining the Nozzle Connector?

A: Routine cleaning to remove debris and periodic visual inspections for wear ensure the connector maintains its performance. Its polished, precision-machined surface supports straightforward maintenance.Q: What are the main benefits of using this connector?

A: Key benefits include high durability, resistance to high temperatures (up to 600C), corrosion resistance, and high precision in cutting operations, ensuring consistent and efficient performance in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese