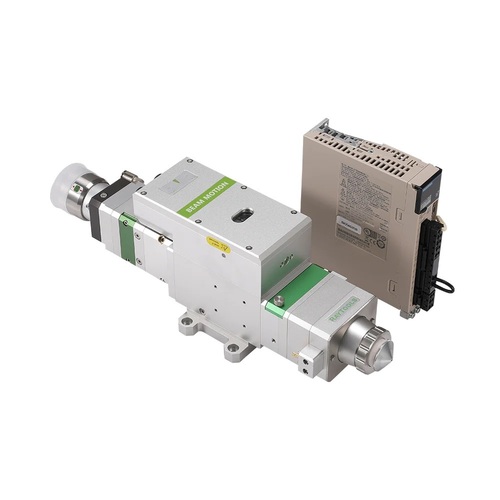

0-3.3Kw Raytools Bm110 Autofocus Fiber Laser Cutting Head

420000 INR/Piece

Product Details:

- Coating Type Protective anti-reflection coating (for lens)

- Length Approx. 340 mm total length

- Cutting Capacity 0-3.3 kW Laser Power

- Operate Method Electric motorized focus adjustment (autofocus)

- Features Autofocus, lightweight design, dustproof, water-cooling compatible, high transmission efficiency, modular structure, easy maintenance

- Cutting Accuracy High precision with autofocus feature

- Cutter Type Fiber Laser Cutting Head

- Click to view more

X

0-3.3Kw Raytools Bm110 Autofocus Fiber Laser Cutting Head Price And Quantity

- 420000 INR/Piece

- 1 Piece

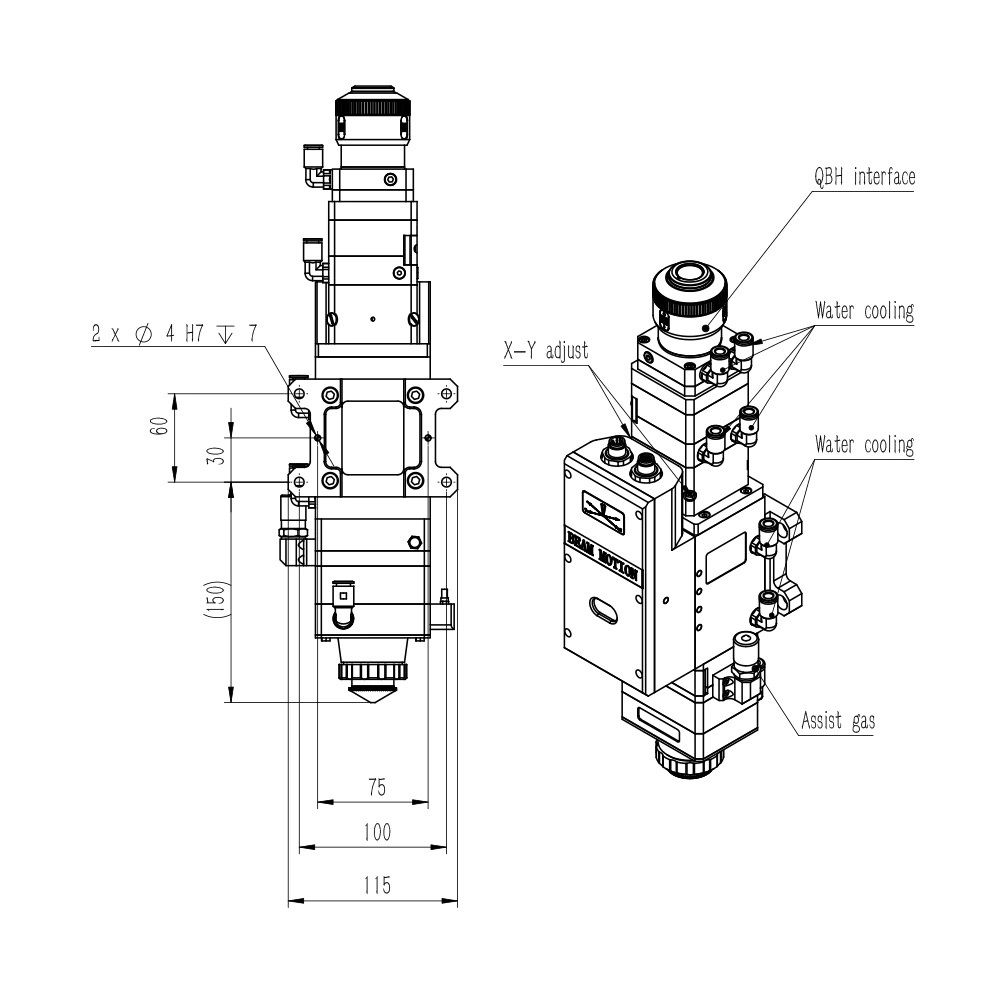

- 110 mm flange

- 100 mm

- Double-layer dustproof

- QBH (Standard)

- BM110 Autofocus

- 25 bar

- 03.3 kW

- Approx. 4.5 kg

- 27.9 x 4.1 mm

- Electric motor

- Built-in capacitance sensor for distance control

- Water-cooled and Air-cooled optics

- 125 mm (standard), 155 mm, 200 mm (optional)

- Sheet metal cutting, stainless steel, carbon steel, aluminum, brass, and other metals

- Compatible with various brands of fiber lasers

0-3.3Kw Raytools Bm110 Autofocus Fiber Laser Cutting Head Product Specifications

- Fiber Laser Cutting Head

- Aviation-grade aluminum alloy and precision optics

- Automatic (Autofocus)

- Approx. 340 mm total length

- Protective anti-reflection coating (for lens)

- Laser Cutting

- 0-3.3 kW Laser Power

- Autofocus, lightweight design, dustproof, water-cooling compatible, high transmission efficiency, modular structure, easy maintenance

- High precision with autofocus feature

- Electric motorized focus adjustment (autofocus)

- CNC Fiber Laser Cutting Machine

- Industrial-grade build quality

- Optical anti-reflection coating

- Rectangular/Box with focus adjustment components

- Supports high-speed laser cutting

- For up to 3.3 kW fiber laser power

- Input collimator lens: 28 mm, Output focus lens: 20/25 mm

- BM110 Autofocus Laser Head

- 110 mm flange

- 100 mm

- Double-layer dustproof

- QBH (Standard)

- BM110 Autofocus

- 25 bar

- 03.3 kW

- Approx. 4.5 kg

- 27.9 x 4.1 mm

- Electric motor

- Built-in capacitance sensor for distance control

- Water-cooled and Air-cooled optics

- 125 mm (standard), 155 mm, 200 mm (optional)

- Sheet metal cutting, stainless steel, carbon steel, aluminum, brass, and other metals

- Compatible with various brands of fiber lasers

Product Description

0-3.3KW RAYTOOLS BM110 AUTOFOCUS FIBER LASER CUTTING HEAD

We bring forth an 0-3.3KW RAYTOOLS BM110 autofocus fiber laser cutting head, which is a kind of laser cutting head used in laser cutting machines. Usually, the focus length of the laser beam is designed to be automatically adjusted to provide the optimum cutting results with thicknesses. The 0-3.3KW RAYTOOLS BM110 Autofocus fiber laser cutting heads, we deal in are employed in numerous industries. automotive sector as well as aerospace industry make a good use of such device for a meaningful and satisfactory cutting outputs.

Advanced Autofocus and Precision Cutting

The Raytools BM110 Autofocus cutting head delivers automatic focal adjustments via electric motor, allowing for precision cutting across varying metal thicknesses. With its built-in capacitance sensor for consistent height control, users achieve smooth edge quality and high accuracy for sheet metal jobs. The autofocus feature particularly benefits high-mix, variable batch applications, reducing setup time and maximizing productivity.

Versatile Compatibility and Application

Engineered to suit a broad spectrum of fiber laser brands and CNC machines, the BM110 features a standard QBH fiber interface and a flexible selection of focusing lenses. Its sturdy and lightweight aviation aluminum construction ensures both resilience and ease of integration, making it optimal for industries requiring reliable sheet metal fabrication-including stainless steel, aluminum, carbon steel, and brass.

Efficient Cooling and Maintenance

This cutting head offers both water and air cooling options to keep optics clean and temperatures stable, even during intensive operations. The double-layer dustproof construction and modular design permit quick access for maintenance or lens replacement, ensuring long service life and consistent cutting quality. Protective anti-reflection coatings safeguard optics for ongoing high transmission efficiency.

FAQ's of 0-3.3Kw Raytools Bm110 Autofocus Fiber Laser Cutting Head:

Q: How does the BM110 Autofocus Fiber Laser Cutting Head adjust its focus during operation?

A: The BM110 utilizes an electric motor for motorized focus adjustment. The autofocus system dynamically sets the focal length according to material thickness and cutting conditions, ensuring sharp, consistent cuts and minimizing manual intervention.Q: What types of materials can this cutting head process?

A: This cutting head is engineered for a broad range of sheet metals, including stainless steel, carbon steel, aluminum, brass, and other metal materials, supporting high-speed, high-precision laser cutting.Q: When is water cooling or air cooling necessary for the optics?

A: Water cooling is recommended for demanding, long-duration, or high-power cutting tasks to maintain lens clarity and temperature control, while air cooling is suitable for standard operations or lighter workloads where rapid heat dissipation is not critical.Q: Where can the BM110 Autofocus Cutting Head be installed?

A: It is designed for CNC fiber laser cutting machines with a 110 mm flange. The QBH interface ensures compatibility with most popular fiber laser sources available in the industry.Q: What is the process for routine maintenance or lens replacement?

A: Thanks to the modular build, access is straightforward: users can open the dustproof housing to inspect or replace protective windows and lenses, thus maintaining cutting accuracy and prolonging the lifespan of the optics.Q: How does the built-in capacitance sensor benefit sheet metal cutting?

A: The integrated capacitance sensor measures the distance between the nozzle and workpiece in real time, automatically adjusting height to ensure optimal focusing and consistent cut quality, even over uneven surfaces.Q: What is the primary benefit of using the BM110 Autofocus with high-power fiber lasers up to 3.3 kW?

A: It enables precise, automatic cutting of various metal thicknesses with reduced setup time, high cutting speeds, and professional results, making it an ideal tool for service providers requiring reliability and flexible processing capacity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese