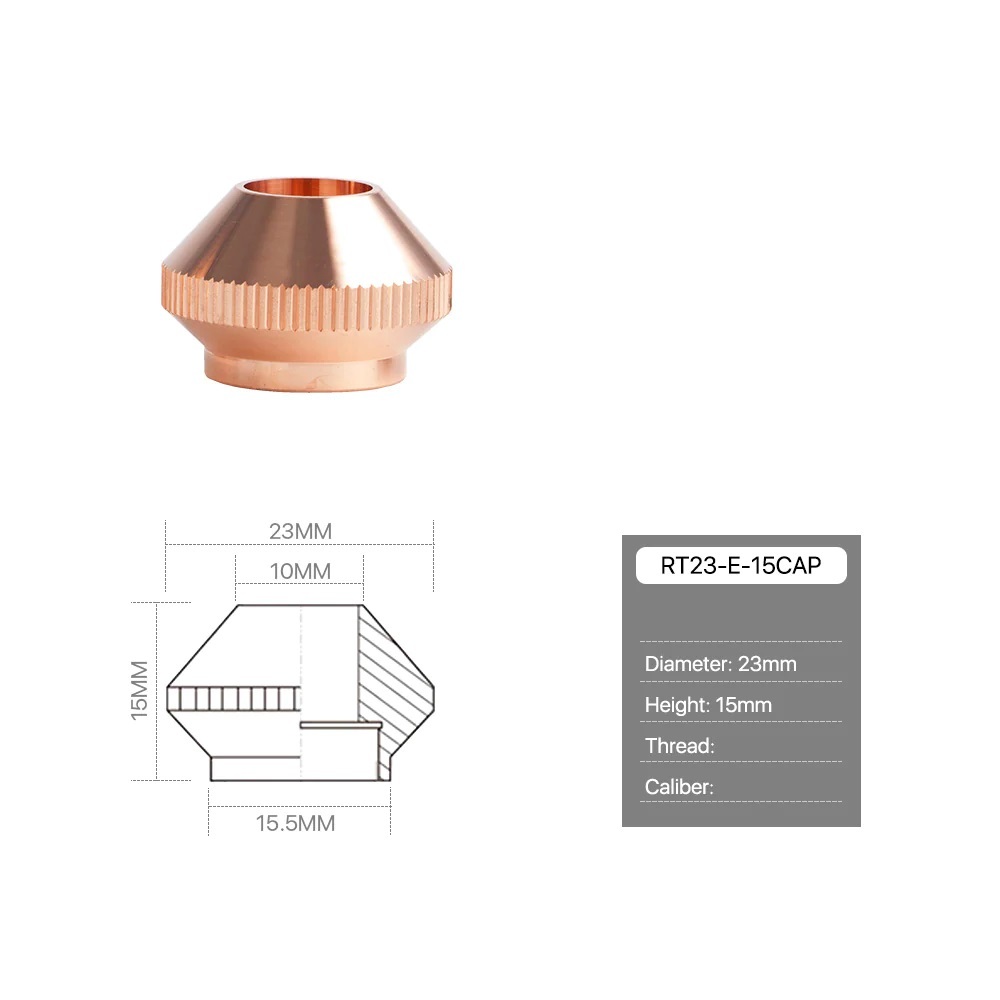

Raytools D Type Laser Cutting Nozzles

550 INR/Piece

Product Details:

- Metals Type Copper

- Click to view more

X

Raytools D Type Laser Cutting Nozzles Price And Quantity

- 1 Piece

- 550 INR/Piece

- M11

- O2/N2/air

- Polished Surface

- Copper Tone

- Conical

- Double Layer

- High Precision

- D Type

- Laser Cutting

- Raytools Head

Raytools D Type Laser Cutting Nozzles Product Specifications

- Copper

- M11

- O2/N2/air

- Polished Surface

- Copper Tone

- Conical

- Double Layer

- High Precision

- D Type

- Laser Cutting

- Raytools Head

Raytools D Type Laser Cutting Nozzles Trade Information

- 7 Days

Product Description

Shop Now to experience the elite quality of Raytools D Type Laser Cutting Nozzles, engineered for enviable precision and ravishing performance. These lustrous, copper-toned nozzles feature a double-layer, polished surface for optimal durability and high accuracy. Perfectly compatible with Raytools Heads, the conical shape and M11 threading ensure seamless application with O2, N2, or air gases. Ideal for advanced laser cutting services, suppliers, and traders in India, these nozzles offer markdown value without compromising on excellence or finish.

Premium Material and Application Benefits

Raytools D Type Laser Cutting Nozzles are crafted from top-grade copper, providing outstanding heat conduction and longevity. These double-layer, polished conical nozzles are designed for use with Raytools Heads, making them suitable for precise metal cutting tasks. Simply attach them to the compatible laser cutting system for enviable results across various industrial sites, ensuring refined, clean edges in every use.

Payments, Export Markets, and Trusted Shipments

Benefit from flexible payment terms when you procure Raytools D Type Laser Cutting Nozzles. We supply and dispatch shipments securely packed for domestic and global markets, ensuring swift delivery. Our main export markets span across India and major international destinations. Each shipment is carefully packaged to protect the lustrous, polished copper finish during transport, keeping your order safe and ready for immediate application upon arrival.

Premium Material and Application Benefits

Raytools D Type Laser Cutting Nozzles are crafted from top-grade copper, providing outstanding heat conduction and longevity. These double-layer, polished conical nozzles are designed for use with Raytools Heads, making them suitable for precise metal cutting tasks. Simply attach them to the compatible laser cutting system for enviable results across various industrial sites, ensuring refined, clean edges in every use.

Payments, Export Markets, and Trusted Shipments

Benefit from flexible payment terms when you procure Raytools D Type Laser Cutting Nozzles. We supply and dispatch shipments securely packed for domestic and global markets, ensuring swift delivery. Our main export markets span across India and major international destinations. Each shipment is carefully packaged to protect the lustrous, polished copper finish during transport, keeping your order safe and ready for immediate application upon arrival.

FAQ's of Raytools D Type Laser Cutting Nozzles:

Q: How do I install Raytools D Type Laser Cutting Nozzles?

A: To install, simply screw the nozzle onto a compatible Raytools Head using the M11 threaded connection, ensuring a snug fit for optimal performance.Q: What types of gases can be used with these nozzles?

A: You can use O2 (oxygen), N2 (nitrogen), or air with these nozzles, allowing versatility for different laser cutting applications.Q: Where can these nozzles be applied for best results?

A: These nozzles deliver enviable precision in industrial settings, metal fabrication sites, and service centers needing high-quality laser cutting.Q: What are the benefits of the double-layer design?

A: The double-layer design enhances durability and heat resistance, resulting in superior cut quality and longer service life.Q: When will my order be dispatched after purchase?

A: Orders are typically processed and dispatched promptly upon confirmation of purchase, with shipping times dependent on your location and chosen shipping method.Q: Is the polished surface important for laser cutting?

A: Yes, the lustrous, polished surface reduces material adherence and wear, ensuring smooth, ravishing finishes and consistent nozzle performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese