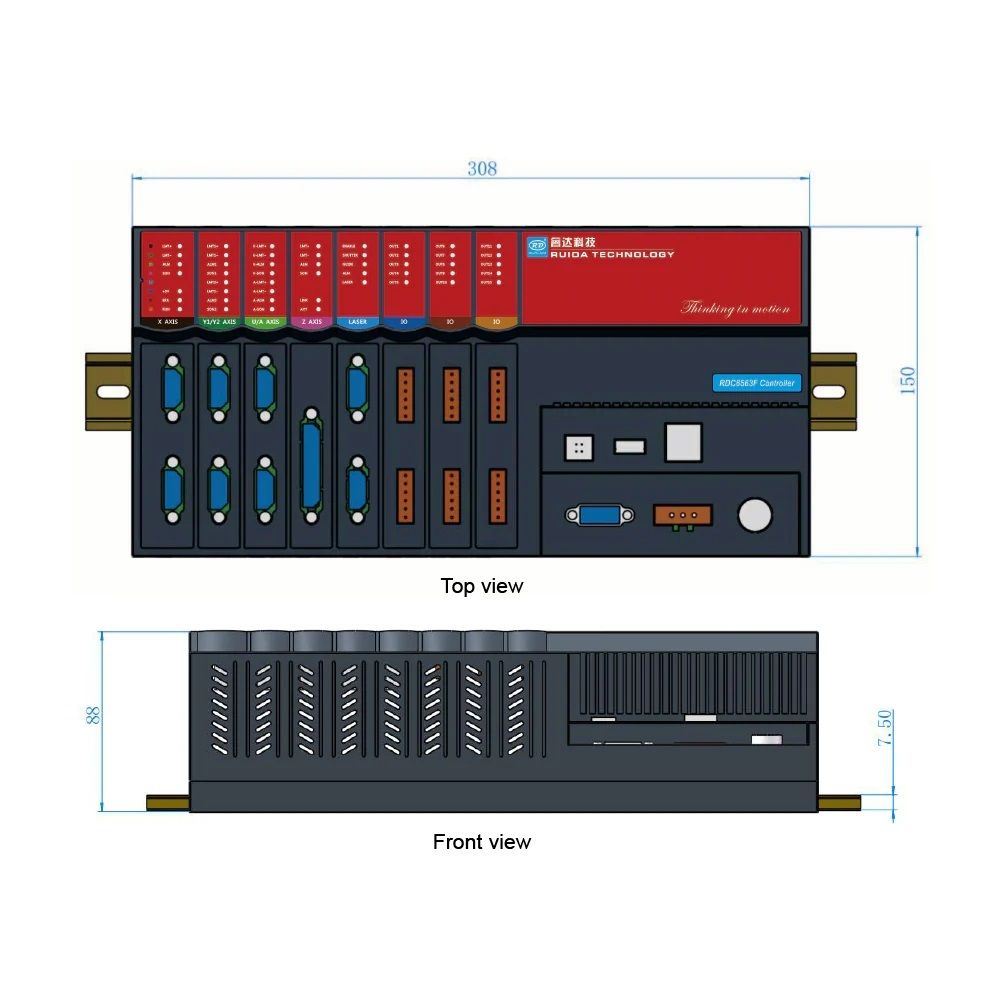

Rudia Rdc6563F Fiber Laser Cutting Control System

Product Details:

Rudia Rdc6563F Fiber Laser Cutting Control System Price And Quantity

- 315800 INR/Piece

- 1 Piece

Rudia Rdc6563F Fiber Laser Cutting Control System Trade Information

- All India

Product Description

Rudia RDC6563F Fiber Laser Cutting Control System is an advanced CNC controller designed to deliver precise, stable, and high-speed laser cutting performance. It manages motion control, laser power, and real-time monitoring for fiber laser machines with exceptional accuracy. Widely used in sheet metal processing, it supports complex graphics, nesting, and multiple cutting technologies. The system features a user-friendly interface, high anti-interference capability, and smooth edge control. Ideal for automotive, machinery manufacturing, electronics, signage, and metal fabrication industries, it enhances productivity, reduces errors, and ensures consistent cutting quality in industrial laser applications and long-term operational reliability.

| Frequency | 50 Hz |

| Country of Origin | Made in India |

| Automation Grade | Automatic |

| Brand Name | Quick CNC |

| Usage | Fiber laser Cutting Controller |

| Material | Plastic |

Advanced Automation for Enhanced Productivity

The Rdc6563F system is engineered for automatic operation, streamlining the laser cutting process and reducing manual intervention. Its PLC-based control system simplifies workflows, leading to increased productivity and minimized operational errors. This makes it a preferred choice for workshops aiming to boost output and consistency.

Reliable Air Cooling Technology

With air cooling as its core mechanism, the Rudia Rdc6563F ensures stable performance even during extended use. The cooling system is both efficient and low-maintenance, ensuring the equipment can handle demanding tasks without frequent downtime for service, providing greater reliability in industrial operations.

FAQ's of Rudia Rdc6563F Fiber Laser Cutting Control System:

Q: How does the Rudia Rdc6563F Fiber Laser Cutting Control System operate without computerization?

A: The Rudia Rdc6563F relies on a PLC (Programmable Logic Controller) control system, which allows for seamless automation of the fiber laser cutting process without the need for a computer. This ensures straightforward operation for users seeking efficient results with minimal technical complexity.Q: What are the main benefits of using fiber laser technology with this control system?

A: Fiber laser technology, when paired with the Rdc6563F control system, offers high-precision cutting, increased energy efficiency, and low maintenance requirements. The system delivers clean and accurate cuts, contributing to improved product quality and reduced wastage.Q: When is air cooling preferable over other cooling methods for this control system?

A: Air cooling is ideal when operating in environments where water resources are limited or when a low-maintenance cooling solution is desired. The air-cooled design of the Rdc6563F keeps the system at optimal temperatures during extended use, making it suitable for busy manufacturing settings.Q: Where can I access warranty or after-sales service for the Rudia Rdc6563F system in India?

A: Warranty support and after-sales services for the Rudia Rdc6563F are available through authorized service providers, suppliers, and traders across India. These professionals ensure timely maintenance and technical assistance within the one-year warranty period.Q: What is the installation process like for the Rdc6563F control system?

A: Installation involves integrating the control system with your existing fiber laser equipment and PLC infrastructure. Suppliers provide guidance and technical support throughout the setup to ensure proper configuration and optimal performance.Q: How is the automatic grade of the Rudia Rdc6563F advantageous to users?

A: Being fully automatic, the Rdc6563F reduces the need for manual intervention, streamlining the laser cutting process. This not only saves time but also minimizes the risk of human error, improving operational efficiency and consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese