FIBER LASER FOCUS LENS

9400 INR/Piece

Product Details:

- Tool Type Fiber Laser Optics

- Operation Type Automatic

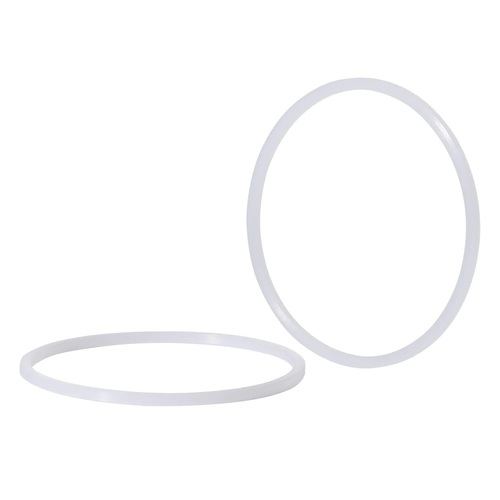

- Shape Round

- Cutting Speed High (Depends on laser system)

- Machine Type Fiber Laser Cutting / Marking Machine

- Length 2mm 6mm (thickness, varies by model)

- Hardness Hard Coated

- Click to view more

X

FIBER LASER FOCUS LENS Price And Quantity

- 9400 INR/Piece

- 1 Piece

FIBER LASER FOCUS LENS Product Specifications

- Automatic

- Fiber Laser Optics

- 2mm 6mm (thickness, varies by model)

- Hard Coated

- Round

- Fiber Laser Cutting / Marking Machine

- High (Depends on laser system)

- Fused Silica / Quartz

- Depends on lens focal length and laser power

- Precise, micron-level

- Integrated into laser head

- 20mm, 25mm, 28mm, 30mm (varies by model)

- High transmission, Long life, Anti-reflection, Precise focusing

- Contactless laser application

- Single / Double AR-Coated

- AR (Anti-reflection)

- Laser Focusing

Product Description

FIBER LASER FOCUS LENS

We have brought a fiber laser focus lens, which is considered an essential component of a fiber laser cutting machine. It is in charge of regulating the laser beams focus. This optical component was created utilising secure and high-quality materials to adapt well to the requirements and uses of laser cutting. A fiber laser focus lens is usually mounted in the cutting head. It essentially provides a sharp focus resulting in clean as well as accurate cuts. It shows satisfactory performance for fulfilling customers needs. It is demanded in the settings associated with laser cutting applications.

Outstanding Optical Clarity and Durability

Our fiber laser focus lenses provide exceptional light transmission (over 99.5% at design wavelength) and maintain clarity due to their premium AR coatings. Manufactured with fused silica or quartz, they resist scratches and physical stress, ensuring consistent performance and longevity even in demanding environments.

Precision Engineered for Laser Systems

Designed with tight tolerances and high surface quality (20-10 scratch-dig), these lenses enhance the focusing capabilities of fiber laser systems. Available in various diameters and focal lengths, our lenses assure precise beam convergence, critical for applications requiring micron-level accuracy and fast, clean processing results.

Versatile Compatibility and Application

These lenses are easy to integrate into standard lens mounts used in fiber laser cutting, marking, and welding machines. Their wide working temperature range and compatibility with laser powers up to 3 kW make them ideal for a broad spectrum of industrial automation tasks, suitable for both single-unit users and service providers in India.

FAQs of FIBER LASER FOCUS LENS:

Q: How do I choose the appropriate focal length for my fiber laser application?

A: The ideal focal length depends on your processing requirementsshorter focal lengths (e.g., 50 mm) provide a smaller focused spot for finer detail, while longer focal lengths (75 mm or 100 mm) allow for larger working distances and thicker material processing. Consult your laser machine specifications and the materials thickness to select the right lens.Q: What benefits does the AR (Anti-reflection) coating offer for these lenses?

A: The AR coating significantly reduces surface reflections, increasing light transmission to over 99.5%. This boosts laser efficiency, minimizes thermal build-up on the lens surface, and extends the operational life of the lens while supporting precise focusing during high-power laser processes.Q: Where can these fiber laser focus lenses be used?

A: These lenses are suitable for integration into fiber laser systems across cutting, marking, engraving, and welding applications. They perform reliably in industrial environments and are compatible with fiber laser cutting and marking machines used by service providers, suppliers, and manufacturers in India and internationally.Q: What is the process for replacing or integrating this lens into my laser machine?

A: Replacement or integration uses a standard lens mount, allowing for straightforward installation. Ensure the machine is powered off, remove the old lens using recommended tools, and insert the new lens (matching focal length and diameter). Always follow your equipments specific guidelines for optimal alignment and operation.Q: What is the expected lifetime or durability of the focus lens during operation?

A: With hard-coated AR surfaces and a high-quality material build (fused silica/quartz), these lenses are designed for long life, even with continuous use. Their durability is aided by resistance to high temperatures, scratches, and power loads up to 3 kWensuring minimal maintenance and sustained precision, provided proper handling and cleaning are maintained.Q: How does the lens support contactless laser application?

A: The lens enables precise focusing of the fiber laser beam onto the material, achieving contactless processing. This method reduces wear on both lens and material, ensures clean cuts or engravings, and allows for high-speed operation without physical force exerted by the tool.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese